WATERJET ORIFICE MATERIALS & DESIGN

ORIFICE MATERIALS

Ruby and Sapphire Material: All Corundum is Created Equal

The most commonly used orifice material is synthetic corundum, ordinarily known in the waterjet industry as ruby and sapphire. It is often unknown by end users that these jewels are made of the same material, the only two differences being a small amount of the element chromium used in rubies to create red pigment and manufactured internal geometries.

Corundum has been used abundantly in many applications due to its ease of reproduction and inherent use benefits, such as its extreme hardness. Pure corundum is a 9.0 on the Mohs hardness scale and the second hardest material next to diamond.

Ruby & Sapphire Materials

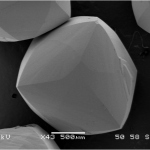

dtiCORE™ DIAMOND MATERIAL: THE HARDEST MATERIAL KNOWN ON EARTH

With the highest score on the Mohs hardness scale, dtiCORE Diamonds consist of premium; single crystal diamond, making them the hardest known material on earth. It is also interesting to note, that a rating of 10.0 is not simply one point higher than ruby, but exponentially higher due to the fact that the Mohs scale is not linear.

Diamond is made up of tetrahedrally bonded carbon atoms crystallized into the diamond lattice. Its exceptional physical characteristics promote its utilization in a vast number of applications. These exceptional attributes encompass optical, thermal, chemical, electrical, and mechanical properties. These characteristics make single crystal diamond material the optimal choice in waterjet cutting applications, ensuring the longest orifice lifetimes and highest cutting efficiencies.

Diamond Materials

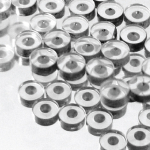

tetraCORE™ MATERIAL: INDUSTRY PROVEN, MID-GRADE DIAMOND

tetraCORE™ is a lab grown, binderless diamond material consisting of a tetrahedrally bonded atomic structure. It is significantly harder than corundum on the Mohs Hardness scale with a rating closer to that of premium diamond. This material offers a lifetime of up to 15x that of ruby and sapphire and will sustain efficient cutting without erosion or degradation of the orifice inlet dimensions for the duration of the product life.

WATERJET ORIFICE DESIGN

Sapphire

Sapphires utilize what is known as sharp edge technology. These produce a long coherent stream, but are vulnerable to minor impacts of debris in the high pressure system which quickly can destroy their integrity.

Ruby

Rubies are designed to incorporate a robust inlet edge radius which is typically about .001″, depending on the orifice diameter. This larger radius can withstand a higher amount of abuse before failing, but causes a shorter coherent jet stream than sapphire. Typically, rubies also produce a higher vacuum than sapphire.

dtiCORE™ DIAMOND

Premium, dtiCORE™ Diamonds utilize a combination of these designs which only they can do because of their inherent strengths. This allows for maximized jet stream lengths while still maintaining robust material integrity. In addition, these design elements allow versatility for effective use in a large array of cutting applications including ultra-high pressure 90K psi.

tetraCORE™ DIAMOND

tetraCORE™ is available with sharp edge technology or a more robust inlet flare. As a product designed to replace ruby and sapphire orifices, it produces a superior, reliable jet stream and optimized stream length. This product will perform with extreme efficiency in 60K psi applications and below.

Contact us to learn which orifice material and design is right for you