WATERJET ORIFICE RETAINERS: METHODS & MATERIALS

The sole purpose of the orifice retainer is holding the jewel in place without affecting jet stream coherency.

WATERJET ORIFICE RETAINING METHODS

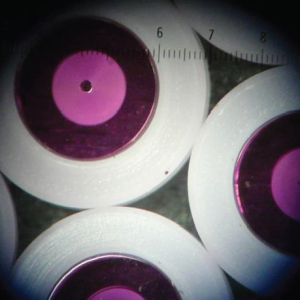

O-Ring Method

This method utilizes acetal, aluminum bronze or titanium retaining materials shaped in an O-ring for press fitting around the outside diameter of the jewel. This retaining method has been in use for many years and has proven to hold up very well with the lifetime of synthetic jewels.

O-Ring Method

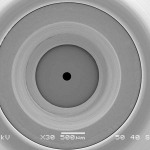

Retainer Method

This method typically utilizes titanium and aluminum bronze retaining materials and retains around the jewel with a positive downward pressure. For added protection, this method also incorporates a small lip over the top of the jewel. Today, this method is becoming the most commonly used, as it is significantly more reliable and may enhance jet stream coherency.

Retainer Method

Adhesive Method

This method is less common today and simply uses an adhesive to secure the jewel to the mount. Typically ruby and sapphire orifices can be retained with this method and in general, the glue maintains effectiveness for the lifetime of the jewel.

Adhesive Method

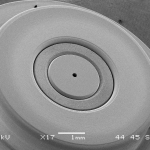

Sintering Method

This method envelopes the jewel with sintered, nickel powder based alloy. This is a very old technique which is now becoming an obsolete process used only by manufacturers with oddly shaped jewels. This method should not be used with pressures exceeding 55K, and it is the most susceptible to orifice failure due to disintegration of the retainer. This retaining method will not hold up in the higher pressures of today and is also more vulnerable to failure due to over torquing.

Sintering Method

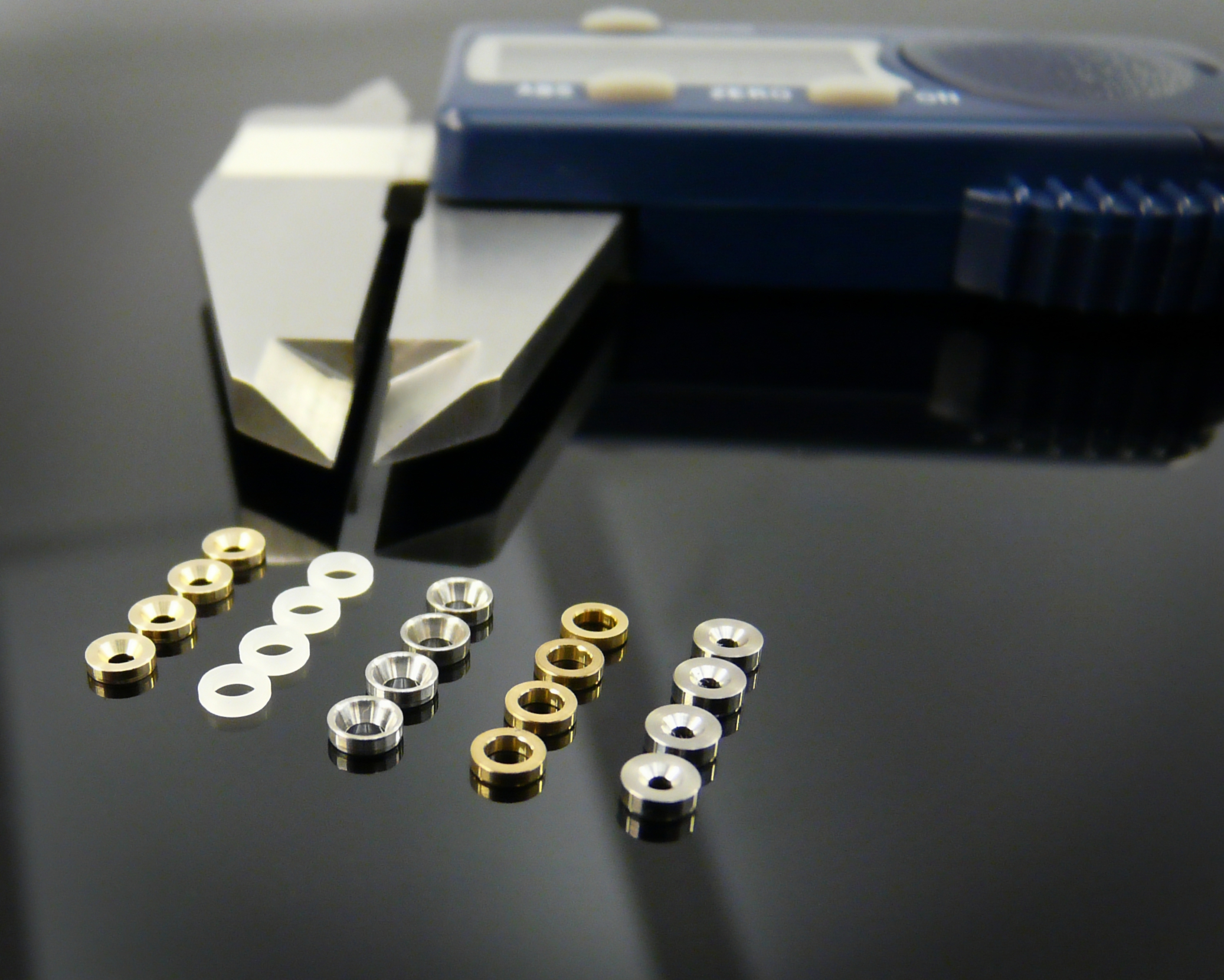

WATERJET ORIFICE RETAINING MATERIALS

Acetal Plastic

Retainers that appear white are made from acetal plastic and have been in use with ruby and sapphire orifices for many years. This material has low water absorption; it is cost effective and performs efficiently when used with synthetic jewels.

Aluminum Bronze

Retainers that appear gold are typically made out of aluminum bronze or aluminum nickel bronze and are commonly incorporated with ruby or sapphire orifices.

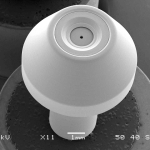

Titanium

Silver retainers are typically made with aerospace grade titanium for use with diamond. This combination of jewel and retainer create an extremely robust orifice preferred for the most rigorous of applications, for example abrasive applications with frequent on/off cycling.

Nickel Powder Base

This is a nickel, powder based alloy often times used with oddly shaped natural or synthetic diamonds. As an alternative to aerospace grade titanium, this material tends not to maintain its material integrity as well as titanium in abrasive and water only applications. Due to better alternatives, this material is quickly becoming an obsolete retaining material.

Contact us to learn which orifice retaining method and material is right for you